In the production of lithium-ion batteries, the mixing and dispersion of the slurry of each pole piece material is very important

-

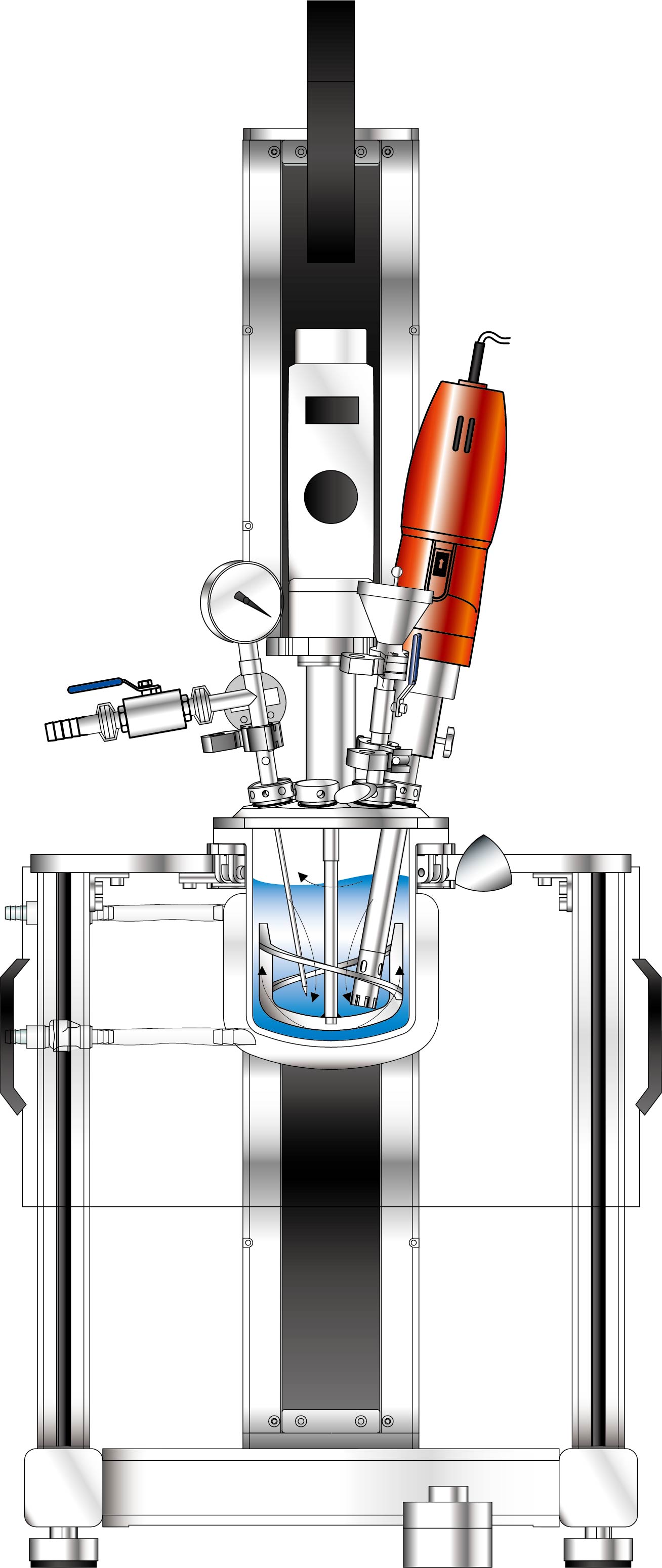

Battery Slurry Preparation ExperimentFLUKO Fisco Reactor SystemDescription

For lithium ion, the positive electrode slurry is composed of binder, conductive agent, positive electrode material, etc.; the negative electrode slurry is composed of binder, graphite carbon powder, etc. The preparation of positive and negative slurry includes a series of fine mixing process requirements such as mutual mixing, dissolution, and dispersion between liquid and liquid, liquid and solid materials, and the process is accompanied by the changes of temperature, viscosity, environment, etc. In the positive and negative electrode slurry, the dispersion and uniformity of the granular active material directly affects the movement of lithium ions between the battery poles. Therefore, the mixing and dispersion of the slurry of each pole piece material in the production of lithium ion batteries is very important , which directly affects the quality of subsequent lithium-ion battery production and the performance of its products.

Work Flow1. Preparation of basic material.

2. Prepare the electrolyte solution.

3. Preparation of active solution.

4. Prepare lithium battery slurry.

Problem1. Maintain the vacuum degree of the experimental tank.

2. Mixing of high viscosity materials.

3. Dispersion of high viscosity materials.

SolutionFisco-1S is equipped with a high shear dispersing emulsifier with a rotating speed range of 10000-28000rpm, the maximum tip speed reaches 27m/s, and the three-dimensional anchor-ribbon agitator with scrapper can effectively strengthen the mass transfer, heat transfer and to complete uniform dispersion and mixing;

The vacuum degree in the tank can reach -0.092MPa, which effectively solves the influence of air bubbles in the slurry on the materials during the experiment.

The selection of special working heads maximizes the uniformity of material dispersion.

Advantages

Advantages1. Effectively solve the influence of material bubbles during the experiment.

2. The high tip speed configuration makes the slurry mixing more uniform and the mixing time shorter.

3. The configuration of the special working head significantly improves the powder dispersion uniformity of high viscosity materials.

-

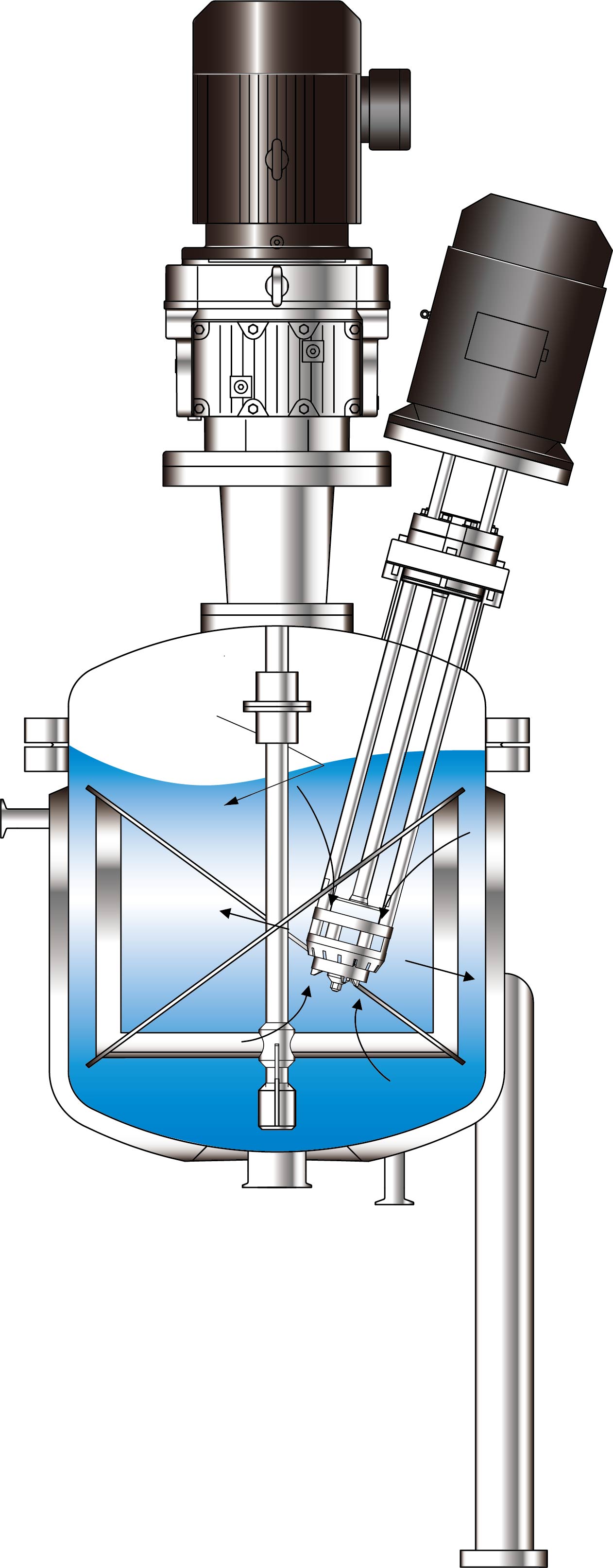

The Fuel CellFLUKO Dispersing EquipmentDescription

As a kind of new energy, fuel cell has received great attention in market development. The fuel cell is mainly composed of four parts: anode, cathode, electrolyte and external circuit. Among them, the catalyst plate has played a great role, and its performance depends on the preparation of the slurry.

Work Flow1. Solvent feeding.

2. Add carbon materials, such as carbon nanotubes, carbon platinum, etc.

3. Disperse the slurry.

4. Uniform distribution of slurry.

Problem1. The materials need to be nano-dispersed.

2. The shape of carbon nanotubes cannot be destroyed.

3. The traditional method is a one-time dispersion method, in which the dispersion strength of different intervals is dispersed without differentiation, which leads to excessive dispersion of some of its materials and massive destruction of its structure.

SolutionFLUKO adopts the interval dispersion method based on in-depth understanding of the process.

1. After feeding, a large amount of agglomeration will occur for the materials, and the micron-level dispersion strength is used during mixing to maintain the required material form.

2. Equipped with a high-viscosity mixer to improve the efficiency of macro mixing and greatly reduce the repeated shear rate of materials.

3. Use suitable materials for equipment processing to prevent mutual dissolution of materials

Advantages

Advantages1. The dispersion force can be controlled to achieve targeted output shear force.

2. Use appropriate macro mixing equipment to greatly reduce the damage rate of carbon material structure.

3. Improve the conductivity of the final product.