There are many types of pesticides. FLUKO uses high shear dispersing emulsifiers with mixers to help produce better agricultural drugs.

-

Pesticide Water EmulsionFLUKO High Shear Dispersing EmulsifierDescription

Pesticide water emulsion is a commonly used pesticide formulation. It is a water-insoluble solution obtained by dissolving insoluble liquid or solid raw materials in organic solvents, and emulsifying and dispersing 0.5-1.5 micron droplets in water to form an environmentally friendly pesticide formulation of an oil-in-water (O/W) emulsion. Its appearance is an opaque white milky liquid.

Work Flow1. Oil phase pre-mixing: Disperse and dissolve pesticide technical and solvent.

2. The water phase materials are premixed in the tank, and the water and the active agent are thoroughly mixed.

3. Add the oil phase to the water phase under the action of a high shear emulsifier to perform emulsification and shearing of the oil and water phases to form a stable emulsion state.

Problem1. In traditional process equipment, the oil-water emulsification time is long and the efficiency is low.

2. Uneven emulsification, wide particle size distribution, and different particle sizes.

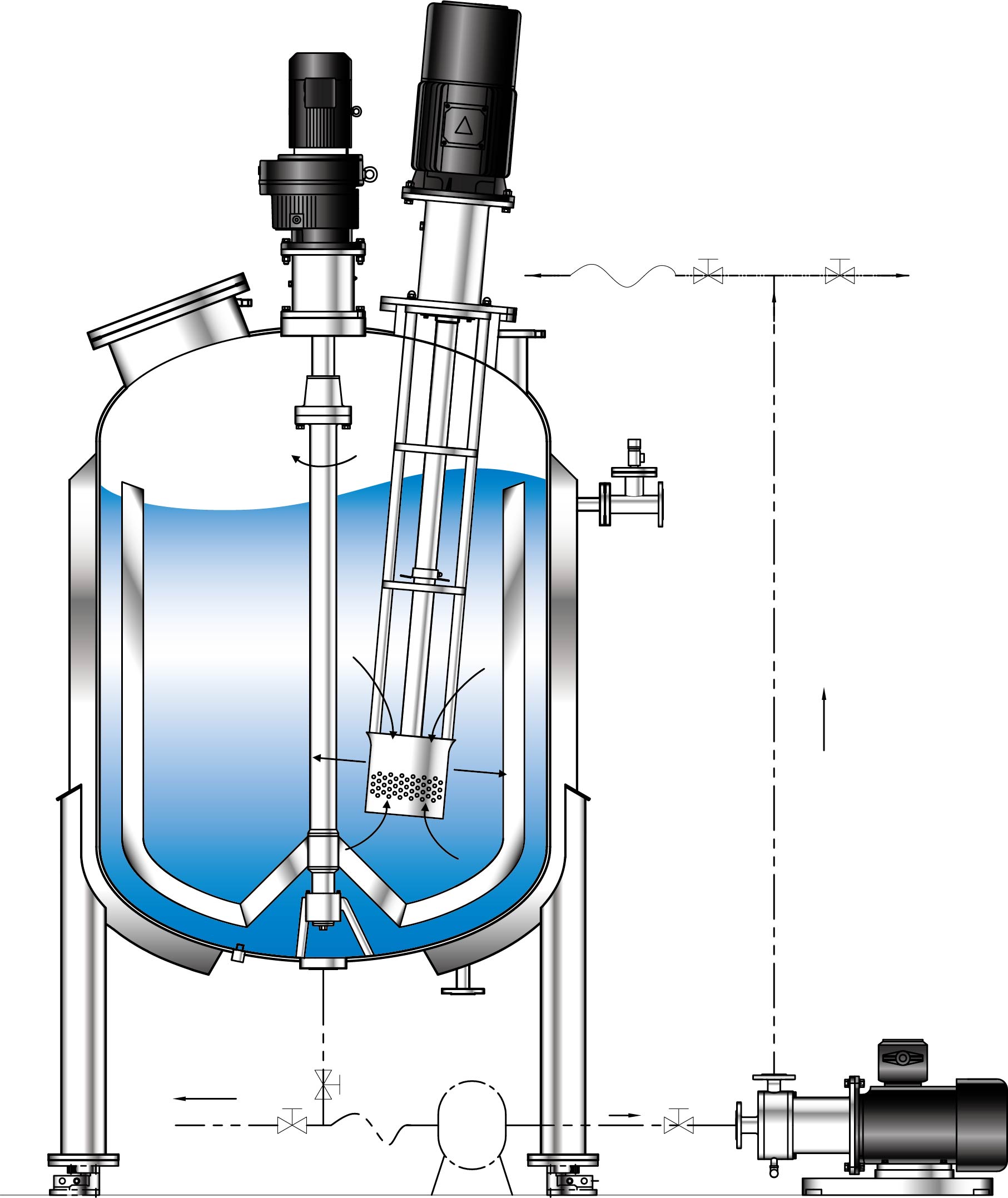

Solution1. The emulsification tank is equipped with a batch high-shear dispersing emulsifier.

2. Use the inline high shear dispersing emulsifier outside the emulsification tank. The narrow working chamber makes the energy density highly concentrated. The material passes through the working chamber in the most probabilistic manner, and there is no dead ends in shearing, so that the particle size distribution range is narrowed and uniformity higher. Eliminate quality differences between batches, high product stability.

Advantages

Advantages1. The strong shearing force of the bath high shear dispersing emulsifier can fully emulsify and shear the droplet size to meet the particle size requirements.

2. Inline high shear dispersing emulsifier, its narrow working chamber can highly concentrate the energy density, the material will be sheared with the greatest probability when passing through the working chamber, the particle size distribution range is narrowed, the uniformity and stability are higher, and the elimination quality differences between batches.

3. Through the cooperation of the two equipments, the final material can reach the range of 0.8-2.5 microns, and the processing time is within 1 hour.

-

Pesticide SuspensionFLUKO High Shear Dispersing EmulsifierDescription

There are many types of pesticides, among which suspension concentrates are a relatively common formulation. It uses water as the dispersion medium, under the action of surfactants and other additives, disperses the insoluble or hardly water-soluble solid technical materials into water, and after grinding, a uniform and stable suspension system is formed.

Work Flow1. Mix and disperse the powder, additives and water.

2. The bead mill finely grinds the powder-liquid mixture.

3. The bead-milled suspension slurry, thickener, defoamer, antifreeze and other auxiliary agents are dispersed and formulated.

4. Qualified inspection, filling and packaging.

Problem1. Using traditional mixing equipment in the pre-dispersion stage, the mixing efficiency is low, there are many agglomerations, it is difficult to disperse, and the loss of the original medicine is large.

2. In the beading stage, the slurry contains agglomerated powder, which leads to poor fluidity and easy precipitation, blocking the bead mill, resulting in increased power consumption and high failure rate.

3. The dispersion efficiency of thickeners such as xanthan gum is low and the dispersion effect is poor.

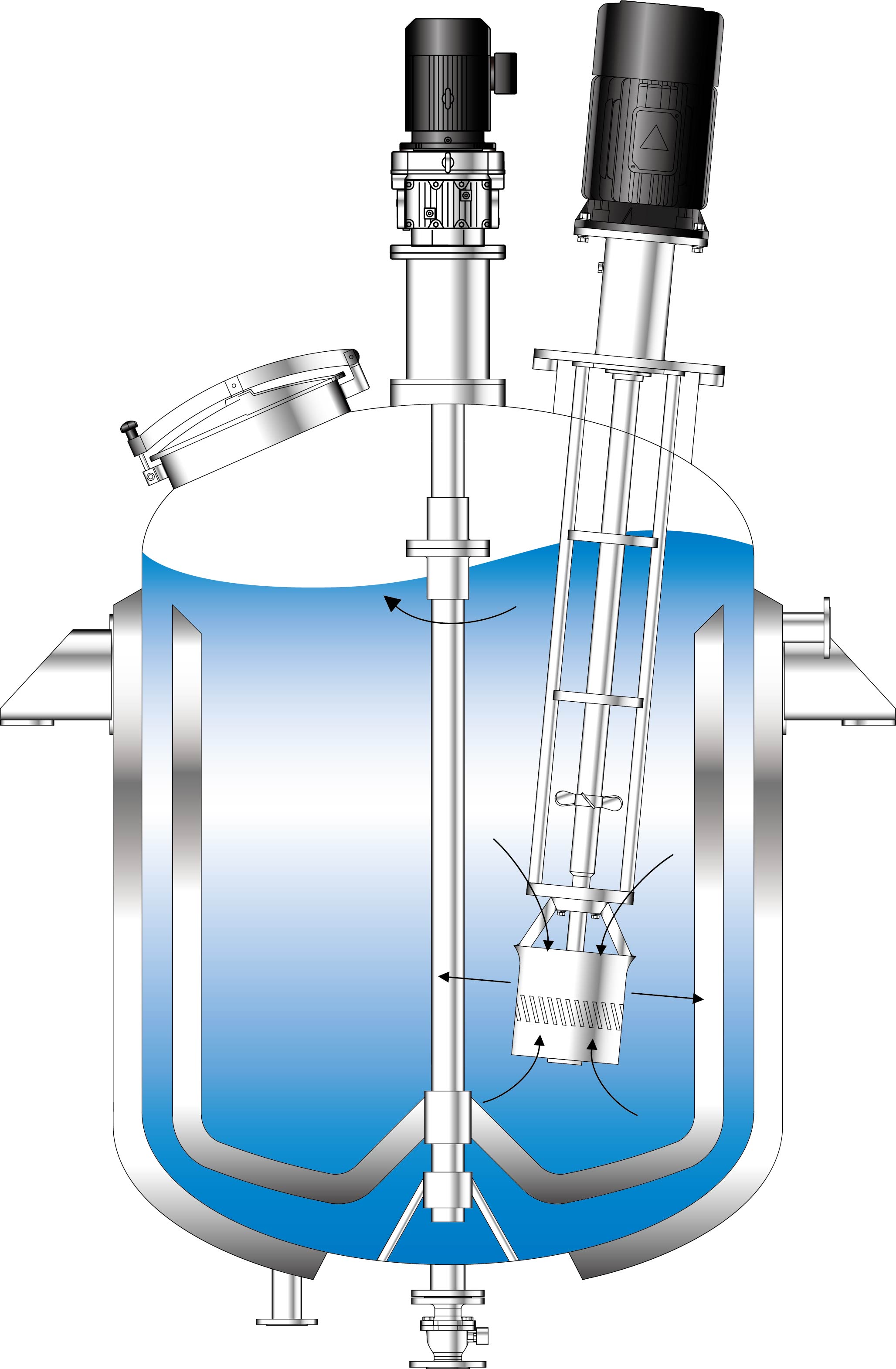

Solution1. Use high shear dispersing emulsifier to complete efficient pre-dispersion.

2. The mixer is equipped in the tank to realize the overall mixing of materials.

3. In the glue process, a specially designed Jetmixers dispersing mixier is equipped.

Advantages

Advantages1. The high shear dispersing emulsifier has a unique diversion chamber, so that the material in the tank forms a vertical circulation, and the powder floating on the liquid surface is quickly sucked under the liquid surface to quickly wet and disperse it.

2. In the pre-dispersion stage, for a mixing tank of 3-5m³, the particle size can reach the range of 70-150 microns in about 45 minutes.

3. The mixer makes the liquid material in the tank form a horizontal circulation, and cooperates with the micro high shear dispersing emulsifier to form a macroscopic and microscopic mixing and coordination.

4. The Jetmixers dispersing mixier can quickly complete the dispersion and dissolution of xanthan gum, replacing the traditional dispersing machine, and realizing a high-proportion, high-efficiency gumming process, usually within 1 hour.

5. The perfect coordination of the entire system can achieve narrow particle size distribution and uniform powder dispersion, reduce sand mill blockage failure, and greatly improve overall production efficiency.