Pharmaceutical preparations used to treat skin rashes, skin irritations, fungal infections, and other diseases

-

Preparation of Pharmaceutical OintmentFLUKO Pilot FISCO Reactor System for OintmentDescription

A pharmaceutical preparation used to treat rashes, skin irritation, fungal infections, etc., usually in the form of ointments because this effectively delivers the active ingredient directly to the desired site.The product may be water-in-oil(W/O) or oil-in-water (O/W), consisting of waxes, emollients and lubricants dispersed in the oil phase, or aqueous phases containing emulsifiers, stabilizers and thickeners, preservatives and colorants, with the active ingredients added after the emulsion is formed, cooled to form.

Work FlowThe production process can be broken down into four separate steps:

1. Preparation of oil phase: The powder components are dispersed into mineral oil or silicone oil and need to be heated for dissolution.

2. Aqueous phase preparation: emulsifiers, thickeners and stabilizers are dispersed in aqueous phase tanks and heated for premixing.

3. Formation of emulsion: Oil and water phase are mixed under intense stirring to form emulsion liquid.

4. Dispersion of active ingredients: Active ingredients usually account for a small proportion of the formula and need to be effectively dispersed throughout the system.

Problem1. The particle size of oil phase and water phase after emulsification is difficult to meet the particle size requirements, and the distribution is not uniform.

2. The active ingredients cannot be uniformly dispersed in the whole system.

3. Low efficiency in homogeneity and dispersion.

Disadvantages of Traditional Equipment:

1. When adding powder, it may agglomerate, accumulate, and have shear dead Angle.

2. The droplet size cannot be reduced to the maximum extent to form a stable and uniform system.

3. Uneven dispersion causes the effect of the product to be affected.

4. Long time mixing is required, resulting in low production efficiency of the factory as a whole.

5. The system cannot be customized according to different processes.

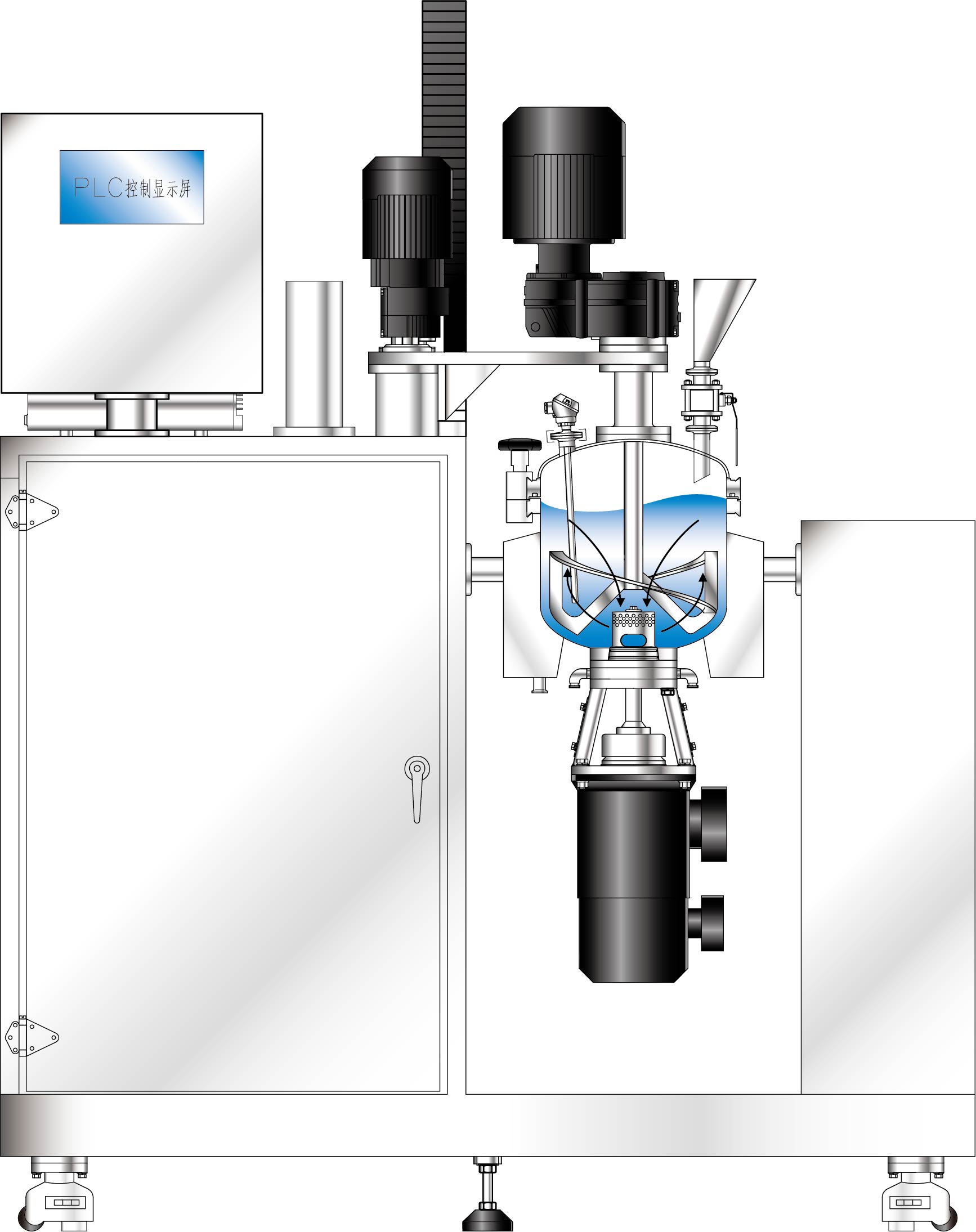

SolutionIn the field of ointment preparation, FLUKO focuses on stirring and shearing in the tank and combines with the inline high shearing outside the tank:

1. Special pressure resistant glass tank is adopted, which can discharge under pressure.

2. The tank is equipped with a low-speed anchor ribbon agitator with scraper.

3. The tank is equipped with a 6000rpm high shear dispersing emulsifier, and an inline high shear dispersing emulsifier outside the tank.

4. The heating mode adopts the circulating water bath which can accurately control the temperature.

5. The equipment is designed in accordance with GMP requirements.

6. Design according to the production process requirements of the final product, and add multiple process nodes to facilitate users to adjust at any time.

Advantages

Advantages1. The vessel made of special glass material provides good observation effect in the preparation process.

2. The anchor ribbon with scraper agitator can effectively drive the overall flow of materials and avoid the residue of materials on the tank wall.

3. The high shear dispersing emulsifier with high linear velocity in the tank can effectively reduce the particle size of materials and achieve high-quality premix and pre-emulsification in the tank.

4. The inline high shear dispersing emulsifier outside the tank enables the material to obtain the emulsification with the maximum probability in the narrow working chamber, so as to achieve narrow distribution and small particle size.

5. The whole machine meets CIP and SIP.

6. Process changes have been taken into account in the design, which can adapt to various production requirements of users.

-

Transdermal Drug Delivery System-Case of Cream PreparationFISCO Reactor System for Cream PreparationDescription

Transdermal Drug Delivery Systems or Trandermal Thrapeutic Systerms is a way that drugs are absorbed through the skin, drugs are absorbed through the skin into the human blood circulation and reach an effective concentration, realizing a new way of drug delivery to treat or prevent diseases. Its products include ointments, creams, plasters, gels, etc.

Work Flow1. Preparation of oil phase.

2. Preparation of aqueous phase.

3. Oil and water are emulsified at about 80℃ to form water-in-oil or oil-in-water system.

4. Uniformly reduce the temperature to about 40℃, and form a semi-solid state then discharging.

Problem1. The particle size distribution control and global size after emulsification of oil phase and aqueous phase cannot be guaranteed, and the reproducibility is poor.

2. The larger particle size causes the cream to be not delicate, and there is a significant difference in color.

3. Under the high viscosity system, it is difficult to achieve even stirring and even heat transfer.

4. The powder of the traditional emulsifying pot is added from the tank cover and is not evenly dispersed in the aqueous phase.

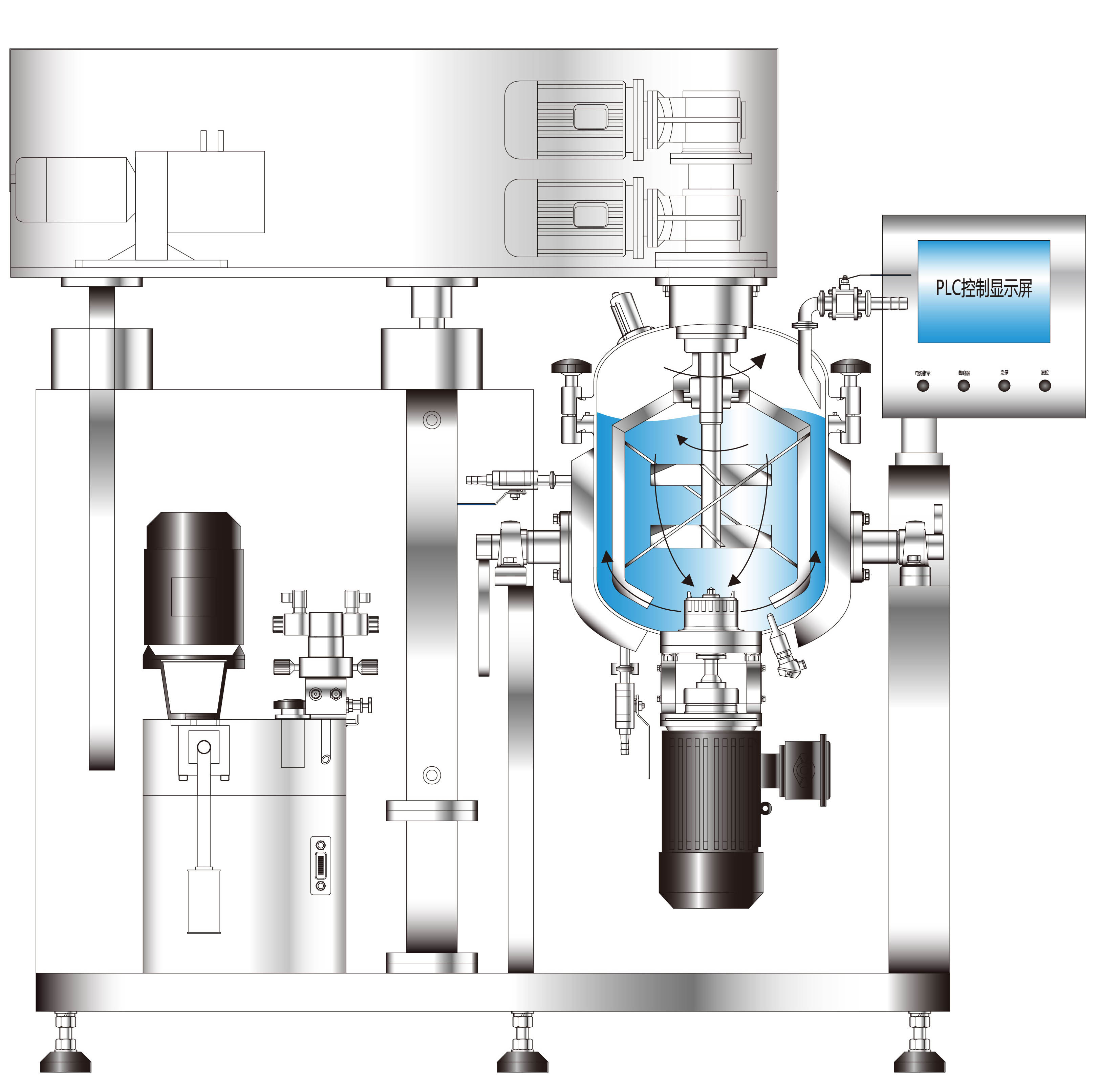

SolutionFLUKO FISCO Reactor System is used.

1. Equipped with uniaxial or coaxial mixer.

2. Internal or external homogenization system, can be added with the function of powder and liquid suction.

3. The system can realize non-homogeneous discharge.

4. Equipped with inline high shear dispersing emulsifier to cycle materials.

5. PLC control to achieve automatic control.

6. The overall modular design satisfies the expandability of the function.

Advantages

Advantages1. The mixer and homogenizer in the tank can achieve the pre-dispersion and pre-emulsification effectively.

2. The uniformity of particle size can be improved by external homogenization equipment.

3. The external homogenizer can increase the function of powder suction, complete the rapid dispersion and dissolution of powder, and avoid agglomeration.

4. Programmable operating system, automatic control, reduce manual labor and improve the batch quality stability of products.

5. The pilot scale is reference for production scale, it can make a smooth transition to production, easy to linear amplification.

6. The whole system realizes CIP and SIP.

-

Anhydrous System OintmentFLUKO Reactor SystemDescription

Pharmaceutical ointments are common external ointments, which are mainly divided into: A ointment limited to the surface of the skin, such as anti-crack ointment; A ointment that penetrates the surface of the skin and acts within it; Anhydrous system ointment, which penetrates the dermis and is absorbed into the systemic circulation to play a therapeutic role throughout the body, refers to the non-aqueous phase material in the preparation system of the ointment, characterized by lubrication, non-irritation, and sealing of the skin surface to reduce water evaporation and promote skin hydration.

Work Flow1. Separate premixing of two kinds of oil-phase materials.

2. Two kinds of oil-phase materials are added to the mixing tank for forced mixing and homogenization.

Problem1. Poor uniformity of two kind of oil phases mixing and emulsification.

2. The wide distribution of particle size makes the cream feel grainy.

3. The immature process causes the cream to be stratified.

4. The material has high viscosity and high dispersion difficulty.

5. The range of treatment capacity is wide and it is difficult to meet the minimum treatment capacity.

Disadvantages of Traditional Equipment:

1. Coaxial mixer and center homogenization equipment: the mixer and center homogenization equipment flow field is not well matched, the center homogenizer seal is easy to be damaged, and the cleaning has dead angle.

2. Uniaxial mixer and upper homogenization equipment: the macroscopic mixing effect of uniaxial stirring in the tank is weakened, and the central area tends to produce dead angle; The upper homogeneous spindle is longer and consumes more energy.

3. The process requirements of the anhydrous system cannot be matched.

4. Insufficient mixing power.

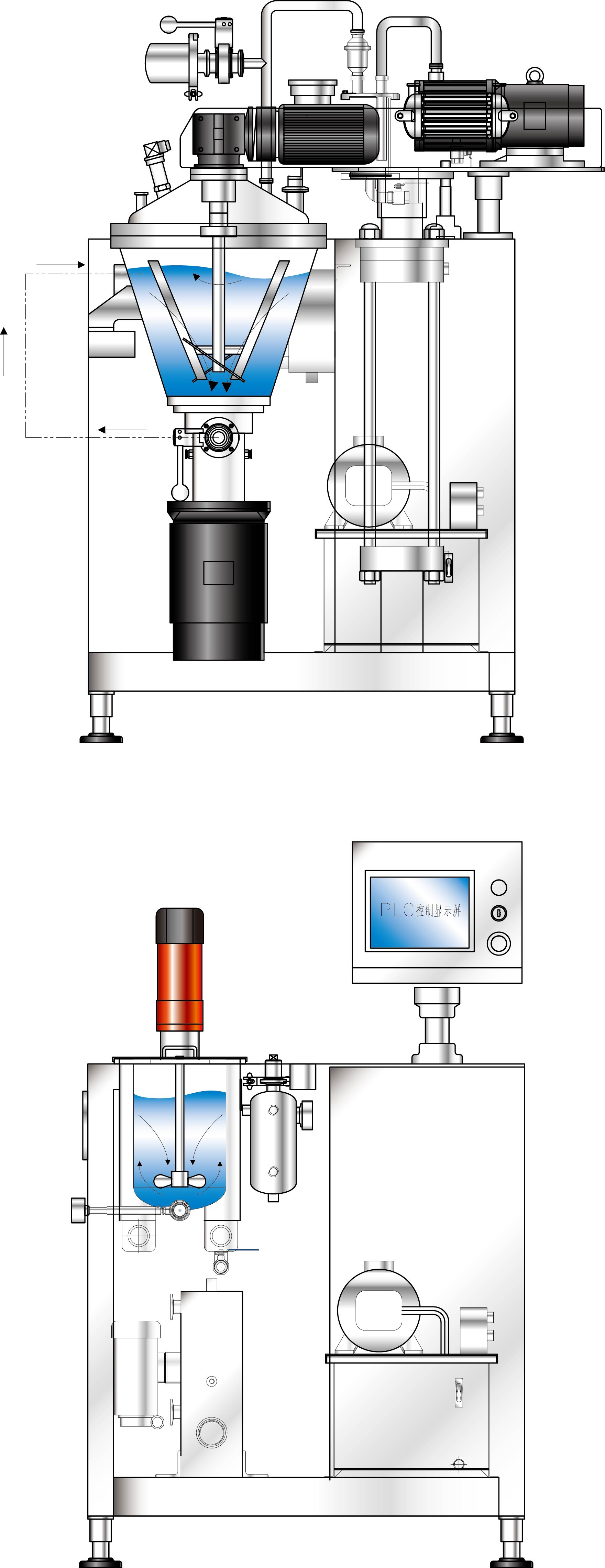

SolutionFLUKO Reactor System is adopted.

1. Use anchor twin ribbon agitator for stirring.

2. Bottom high shear dispersing homogenizer with high linear velocity.

3. High vacuum design.

Advantages

Advantages1. Anchor agitator with twin ribbon can provide the internal and external exchange of materials, playing a good effect of mass transfer and heat transfer.

2. The whole premix and emulsification in tank are realized, which can satisfy the lower initial mass.

3. The high shear dispersing homogenizer outputs a high linear velocity of 28m/s, effectively avoiding problems such as granular sensation of finished products and poor uniformity of drug powder dispersion.

4. Effectively remove multi-crest phenomenon, reduce polarization of particle size, and make distribution more uniform.

5. Strong mixing flow field design, effectively avoid two-phase stratification.

6. The dispersion uniformity of powder in high viscosity system is better.