FSH-HDK

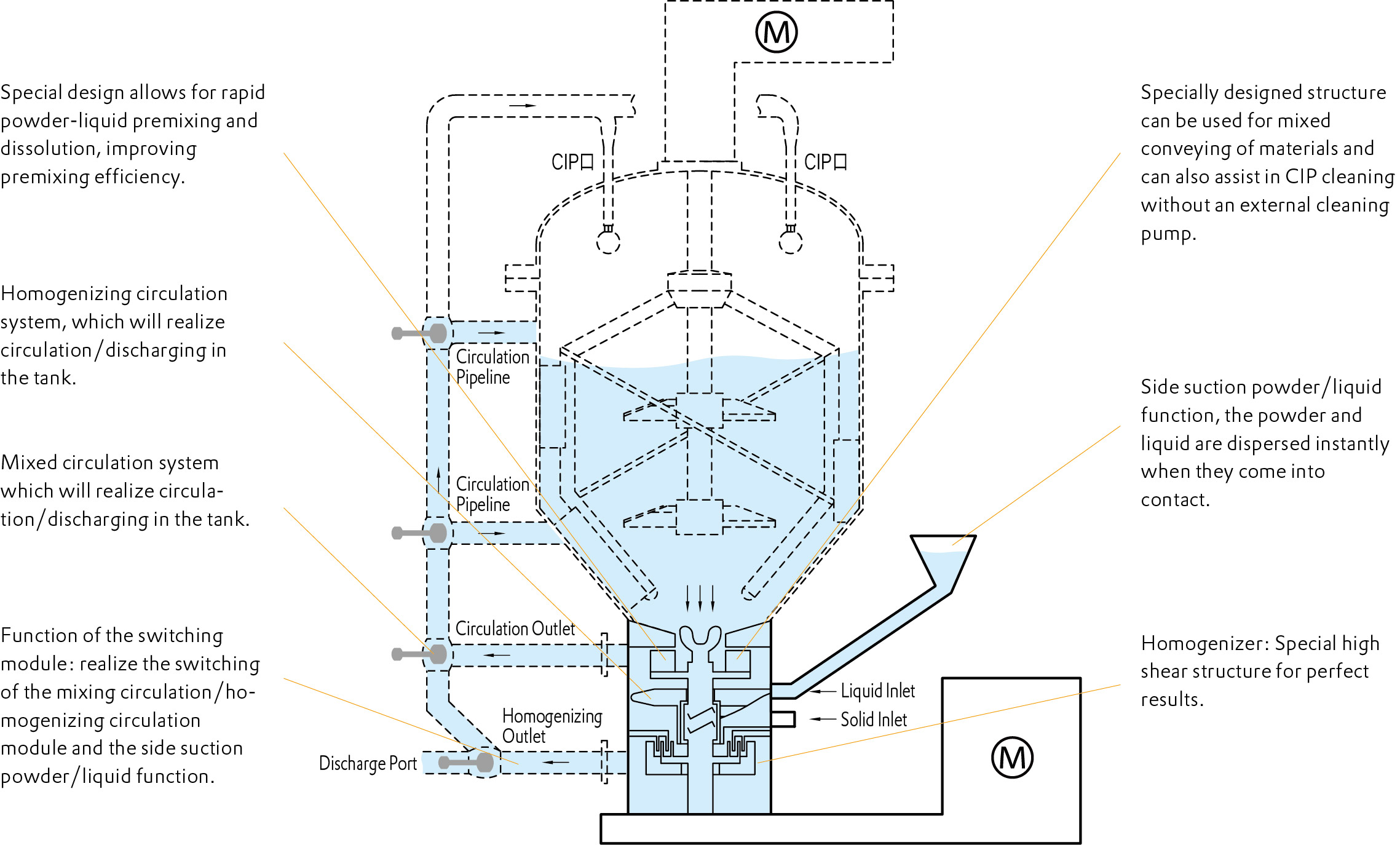

The system integrates multiple functions such as mixing, dispersing, homogenizing, emulsifying, and powder suction. When these functions are not needed, it can be used as a cleaning pump to meet CIP/SIP self-cleaning requirements.

Special small blade design ensures the mixing effect with minimum processing volume and enhances the mixing efficiency of the container cone.

The special upper rotor design is used for mixing and conveying materials, and can also be used for small processing volume circulation. It can generate 4 bar pressure when rotating at high speed, which can assist CIP cleaning without an external cleaning pump.

The mixing chamber and the dispersing chamber can realize weak shear mixing or high shear dispersing homogenization of materials through internal switching, and can also realize vacuum suction of powders/liquids, and realize in-line multiphase material contacted quickiy, mixing, dispersion, emulsification, homogenization and other functions.

| Model |

Maximum Processing Capacity (H₂O) Mixed/High shear (L/H) |

Powder Processing Capacity(KG/H) |

Motor Power (kW) |

Size of Circulation Pipelineand Liquid/Solid Inlet |

| FSH-HDK40-4 | 3000/1000 | 10-200 | 4 | 1"/1" |

| FSH-HDK50-7.5 | 15000/5000 | 30-600 | 7.5 | 1.5"/1" |

| FSH-HDK100-22 | 45000/18000 | 70-1400 | 22 | 2"/1.5" |

| FSH-HDK200-45 | 85000/35000 | 150-2500 | 45 | 3"/2.5" |

| FSH-DHK260-90 | 170000/70000 | 300-4500 | 90 | 4"/3" |